Fruit And Vegetable Processing Equipment

Jujube production line

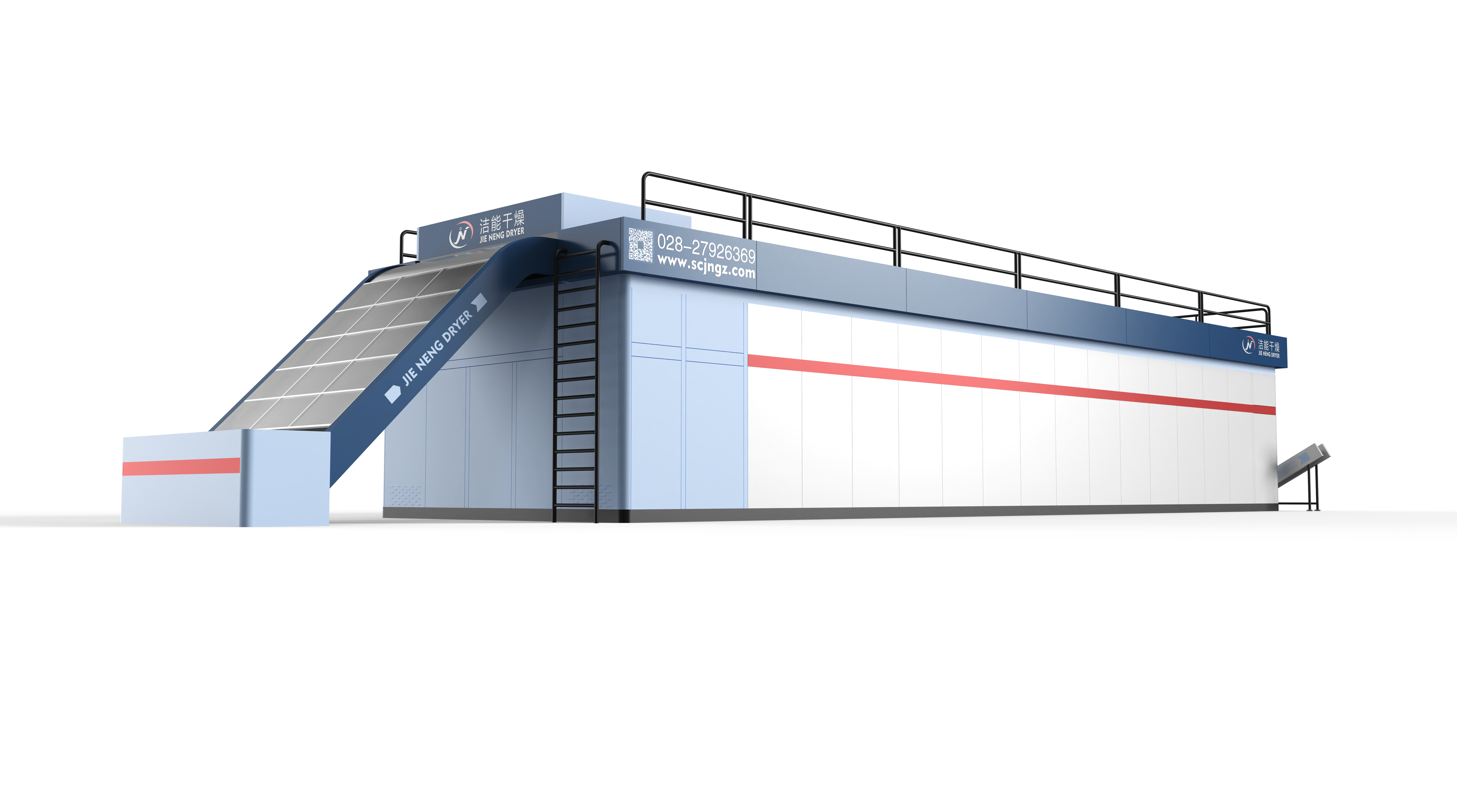

Jujube drying line is a new series of flagship products, suitable for different water content, different varieties of jujube. The equipment is intelligent, universal and compatible, stable and reliable, energy-saving and efficient. The production line is composed of classifier, cleaning machine and dryer. The multi-layer section rotary belt hot air drying technology is adopted to organically integrate the traditional hot air drying process with automation technology, so that the drying curve is consistent in full compliance with the process requirements of red dates drying, and the quality of red dates is preserved. The dried dates after drying are: good fruit type, sweet taste and bright color.

Jujube production line

Goji berry production line

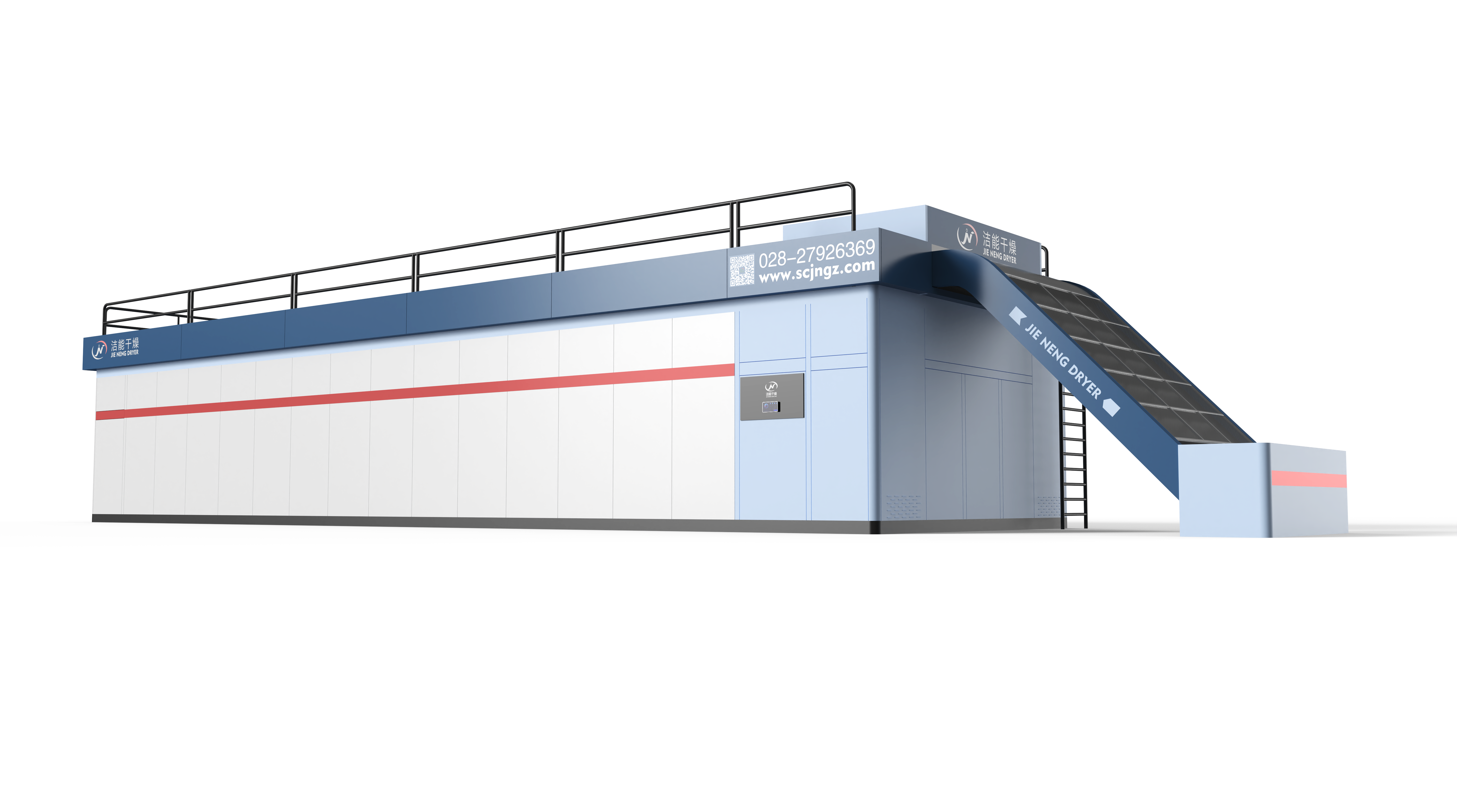

Jieneng fresh Wolfberry production line is a set of highly automated, powerful compatibility, excellent stability and energy-saving drying equipment independently developed and produced for the unique properties of fresh wolfberry and suitable drying curve.

The continuous production process from raw materials to finished products is realized in this production line by the equipment of cleaning and breaking wax machine, automatic plate loading machine and transverse pulsating dual-mode wolfberry drying room. With its integrated inlet and outlet design and assembly line operation mode, its automation level, finished product quality, daily processing capacity and other aspects are in an excellent position in China.

Goji berry production line

Konjac production line

Jieneng Konjac drying line eliminates the dependence on sulfur dioxide and alcohol in the traditional drying process, and the JNRF enzymatic inhibition swelling technology and GYDY technology developed realize environmental protection, safety and energy saving of Konjac drying line, thus improving the health and safety of Konjac products.

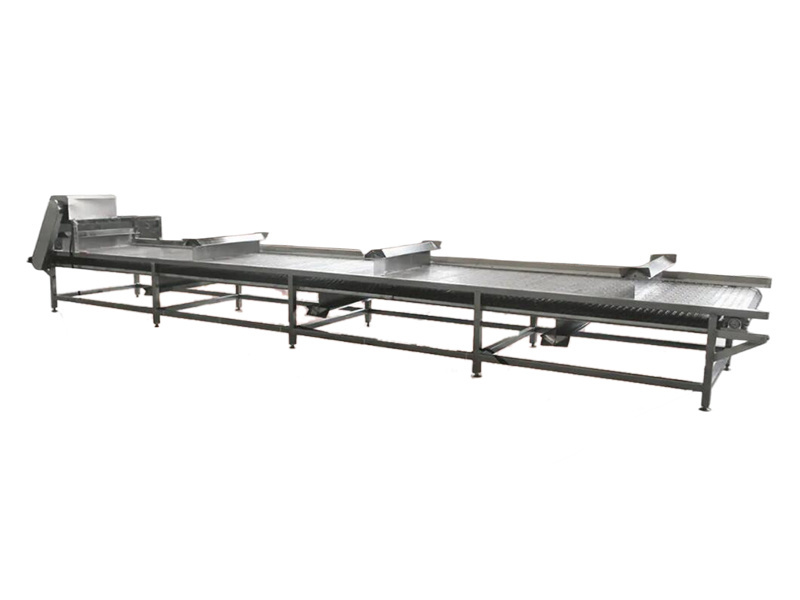

This production line is composed of slicing machine, Konjac cleaning machine and pulse static pressure automatic circulation dry sheet dryer, which realizes the continuous production process from deep cleaning of Konjac raw materials, precise slicing to efficient drying.

Konjac production line

Melon seed production line

The high-quality melon seed processing line launched by Jieneng Dryer uses advanced energy-saving technology and automation technology to improve processing efficiency and profits. The production line pays special attention to the preservation of the quality of melon seeds in the drying process, which is suitable for zucchini melon seeds, Chinese pumpkins, hanging melon seeds, sunflower seeds, watermelon seeds, pumpkin seeds, winter melon seeds, cucumber seeds and silk melon seeds. The effective composition and flavor of these seeds are ensured to a greater extent through the use of dual chamber static pressure pulse air supply mode.

The equipment of the production line is equipped with an automatic ash collection device, which not only meets the needs of efficient production, but also complies with the food safety production license (SC) and good Manufacturing practice (GMP) standards, ensuring the safety and hygiene of the products.

Melon seed production line

Walnut production line

According to the suitable drying curve of walnut, on the basis of traditional static hot air drying process, integrated with modern automation technology, a multi-layer mesh belt automatic hot air drying system was successfully developed and produced. The equipment has the advantages of stable operation, high efficiency and energy saving, universal compatibility and easy operation.

This production line is composed of peeling machine, cleaning machine, dryer, empty and deflated shell machine, classifier, walnut kernel clothes machine and other equipment. The whole production line simulates the natural drying process, using low temperature and large air volume, from the bottom up through the flow of hot air drying, while from the top to the bottom of the fall back transfer process, natural turnover, heat evenly. It achieves the high quality drying effect of low shrinkage, bright appearance and good taste of walnut meat.

Walnut production line

Dehydrated fruit and vegetable production line

Dehydrated fruit and vegetable dryer is based on the classic net belt hot air drying technology, after careful research and development and improvement, specially designed to meet the needs of various regional and seasonal vegetables and fruits dehydration and drying. Suitable for grapes, apricots, apples, radishes, Onions, pumpkins, yams, bamboo shoots and other materials.

This product deeply integrates our rich experience in the field of agricultural drying equipment, and is committed to providing customers with high efficiency and energy saving, tailored professional drying solutions. All parts in contact with the material are made of food-grade materials and strictly follow the national food safety and hygiene standards.