Condiment Processing Equipment

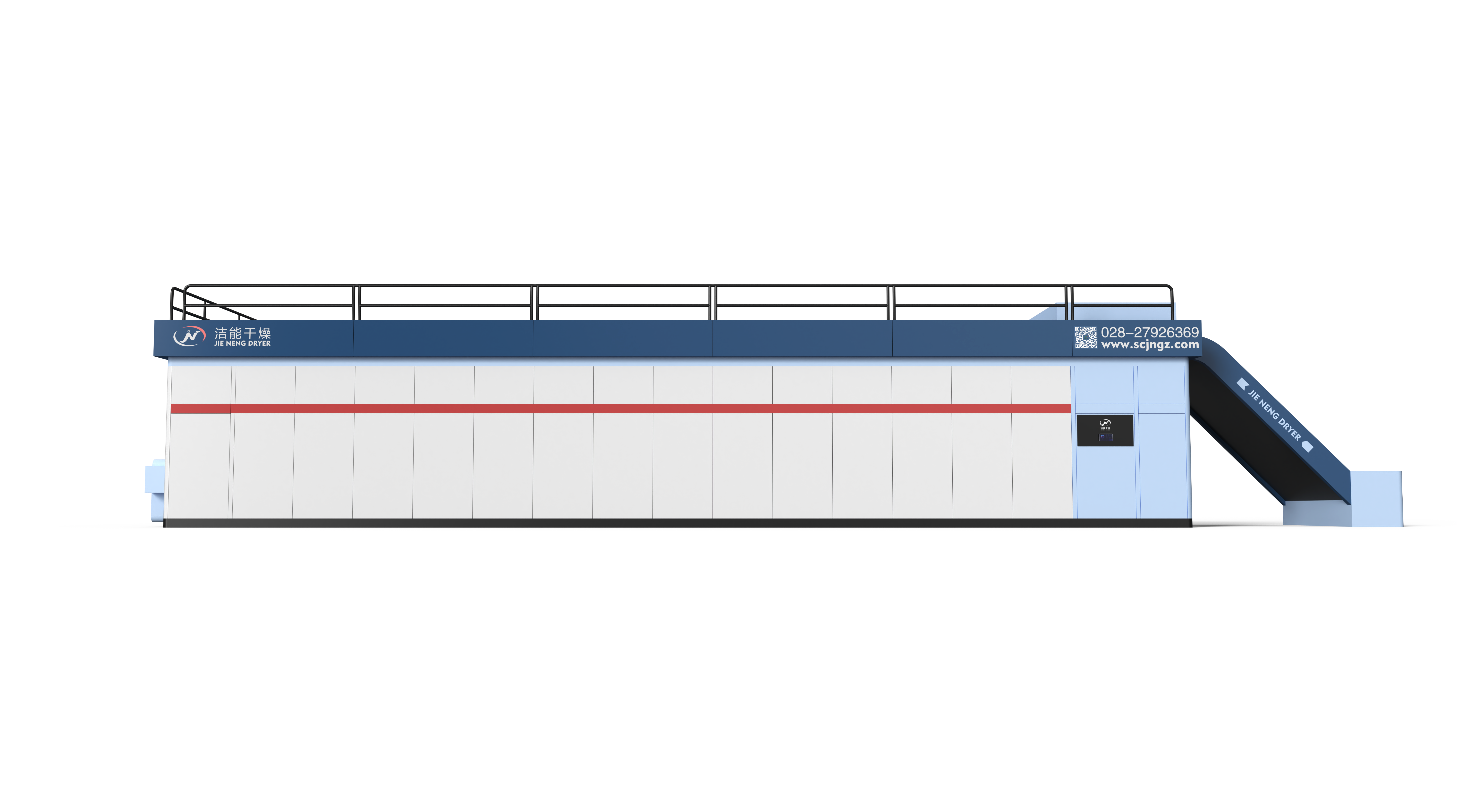

Chili drying production line

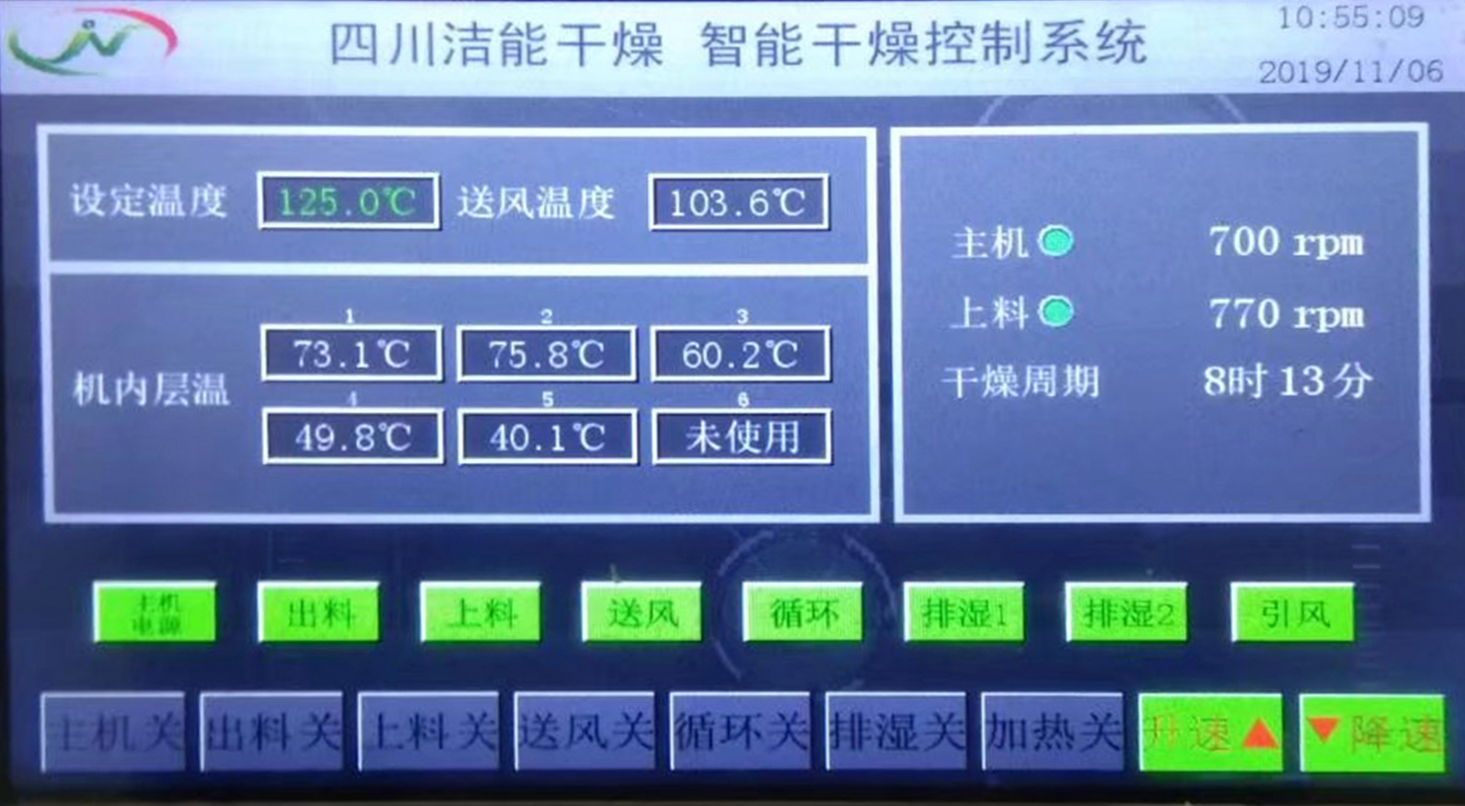

The chili drying line combines the variety of chili peppers and the appropriate drying curve, and adopts a number of patented technologies, including static pressure pulsating balanced layered air supply technology, layered active temperature control technology, JN three-dimensional four-effect energy storage technology, and fault self-check early warning and protection technology. It makes the equipment realize automation, intelligence, high compatibility, low cost and high utilization rate.

In the production line, the peppers undergo a three-stage drying process: preheat drying, uniform drying and deceleration drying. In this process, the surface of the pepper is heated evenly, ensuring the consistency of the drying effect. After drying, the drying rate of pepper is improved, the drying period is shortened, the fruit deformation is small, the surface color is uniform, and the drying effect of high quality and high efficiency is achieved.

Chili drying production line

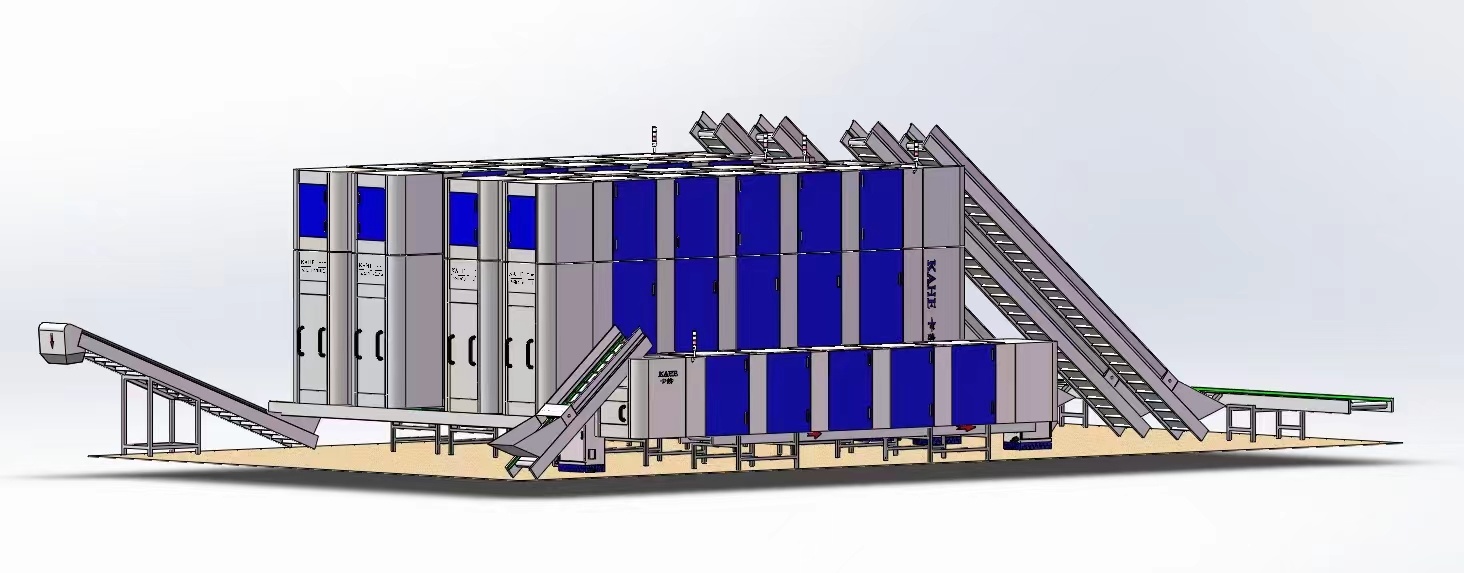

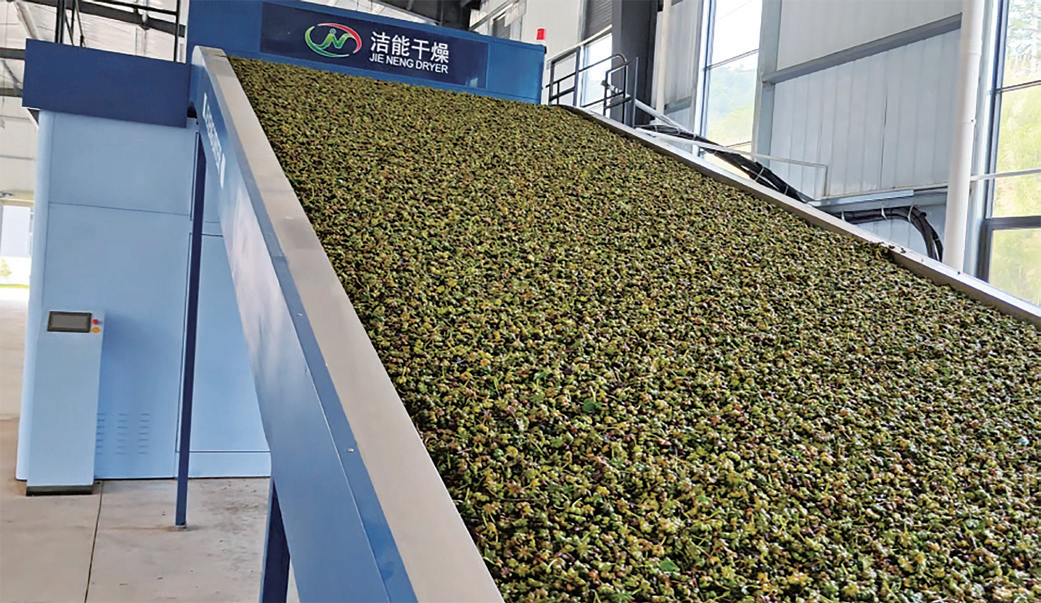

Sichuan pepper intelligent drying production line

Sichuan pepper intelligent drying production line is the latest patented product developed by our company, and is the forefront of domestic Sichuan pepper automatic drying technology. Using intelligent temperature and humidity control technology, segmented drying process setting and innovative pulsating frequency modulation air supply system, the drying process of Sichuan pepper was realized.

The production line integrates the functions of temporary storage dehumidification, automatic drying, branch and fruit separation, handle removal classification, color selection and automatic transmission of pepper, realizing the whole process from raw materials to finished products without falling.

Sichuan pepper intelligent drying production line

Star anise drying production line

In order to meet the drying needs of different varieties of star anise, this production line adopts automation technology, combined with the high efficiency of air energy heat pump and the uniform hot air circulation of mesh belt drying equipment, to create an ideal drying environment for star anise. By precisely controlling the temperature and humidity during the drying process, the production line can complete the drying within 18 to 20 hours, ensuring that the nutritional content, unique fragrance and natural color of the star anise are fully preserved. From finishing to complete drying, the process is controlled automatically, reducing manual intervention and improving production efficiency and consistency of the finished product. While maintaining its natural characteristics, the obtained star anise is more competitive in the market and meets consumers' demand for healthy, high-quality spices.

Star anise drying production line

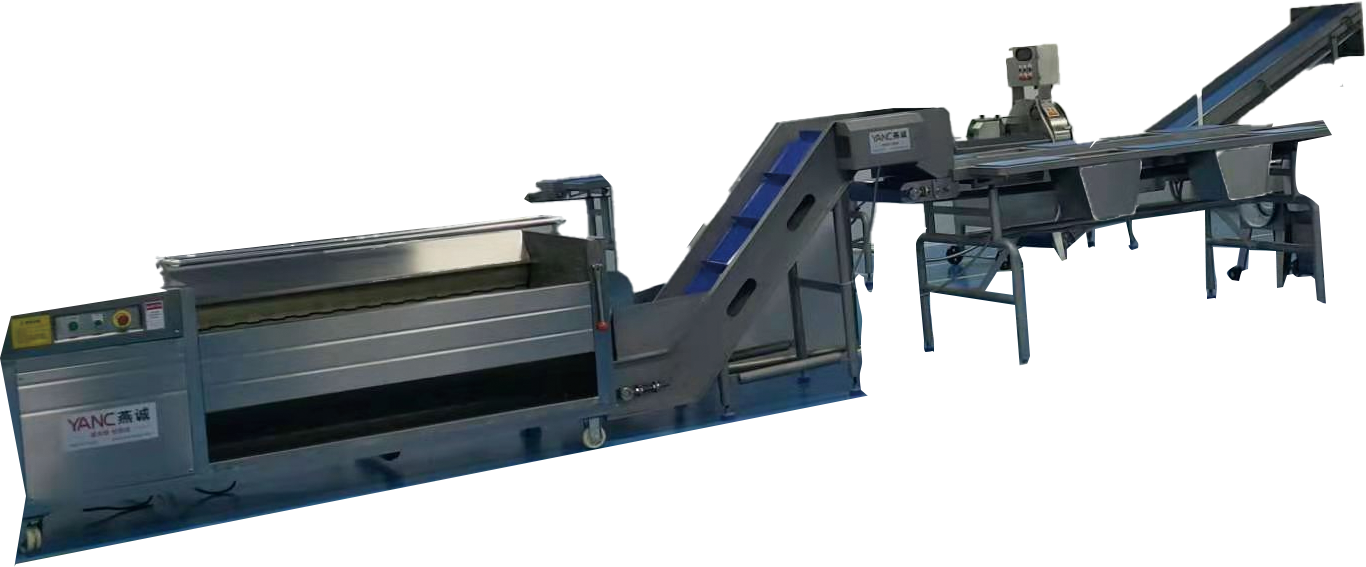

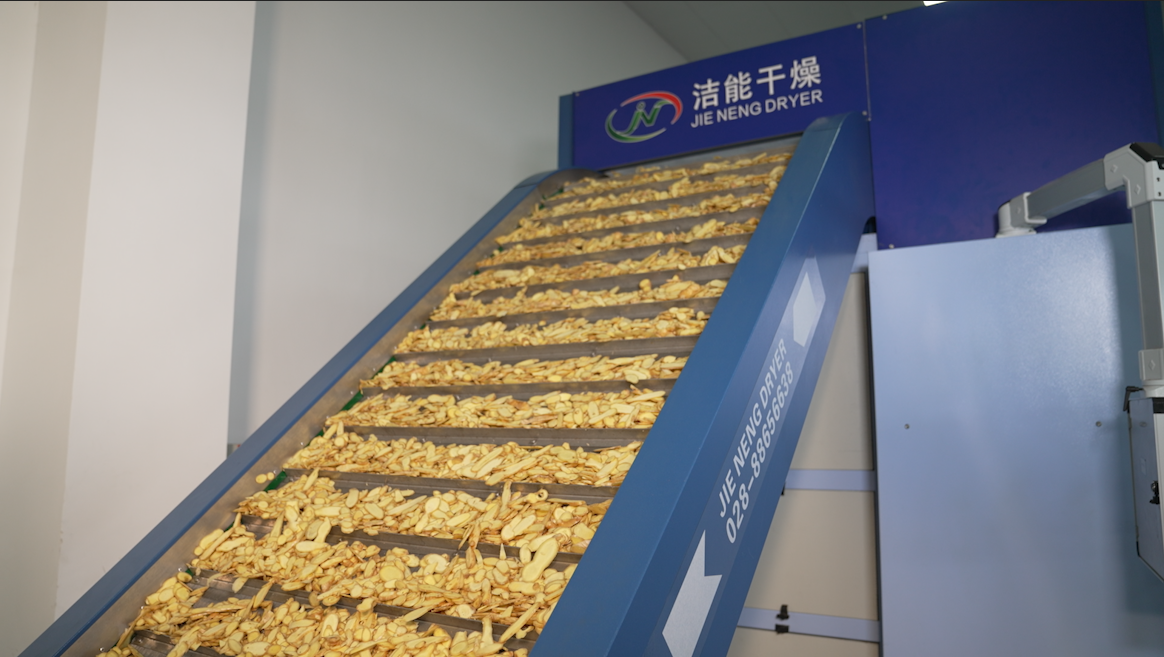

Ginger drying production line

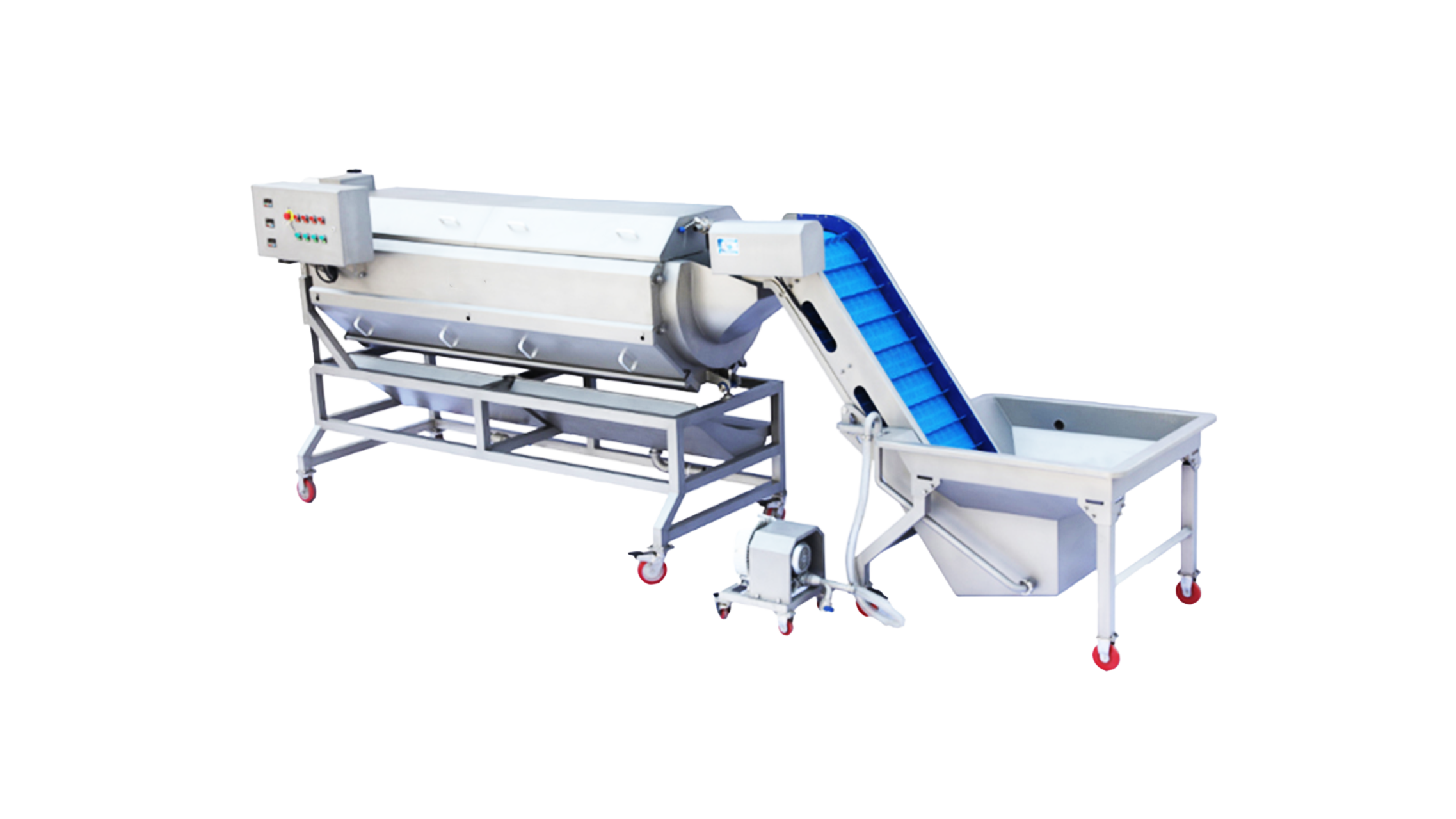

The self-developed Jieneng Revitalizing series ginger dryer is an efficient and energy-saving drying equipment integrating a number of patented technologies. The equipment adopts innovative technologies such as "static pressure pulsating balanced stratified air supply technology, stratified active temperature control technology, three-dimensional four-effect energy storage technology, fault self-check early warning protection" to achieve automation and intelligent drying, ensuring high compatibility and low cost operation of the equipment. The process is a set of continuous automated operations from raw material cleaning, slicing, pre-drying, automatic temperature and humidity control drying, cooling, grading and screening to the final packaging, aiming to efficiently and evenly reduce the moisture content of ginger while maintaining its color, flavor and nutritional value.

Ginger drying production line

Spice drying series

Spice dryer is specially developed to meet the needs of spice crops dehydration and drying equipment. It is suitable for a variety of spice crops, such as pepper, Sichuan pepper, cumin, cinnamon, cloves, grass fruits, etc., can adapt to different regions and seasonal drying needs.

We are well aware of the uniqueness of spice crops, and this equipment brings together our deep technical accumulation in the field of agricultural drying equipment to ensure that the aroma and color of spices are preserved.

All parts in contact with spices are made of food-grade materials, strictly following the national food safety and hygiene standards, to ensure that the spices after drying are safe, sanitary and pollution-free.